How Small Bursts of Data Save Millions of Dollars

THE CHALLENGE

On any given day, there are more than 16 million trailers on the road in North America, including nearly 4 million Class 8 big rigs. Tracking and monitoring all the assets in motion is one of the biggest challenges facing logistics companies. With an average of 2 to 3 trailers for every tractor, carriers waste time and money walking their yards looking for available trailers, calling customers to see if they are detaining trailers and searching for lost trailers. More money is wasted on leasing extra trailers to ensure on-time delivery. It adds up to millions of dollars of extra cost or lost revenue for even a small to medium-size carrier.

THE SOLUTION

TGI Connect is a Canadian company that provides asset management solutions to the transportation industry. Formed in 1992, TGI originally provided trailer marketing opportunities to trucking companies. The expertise it gained led the company to develop a powerful, cost-effective solution for managing trailers. Through a strong partnership with Globalstar, TGI Connect uses the Globalstar devices, and satellite network to locate assets everywhere its customer’s trailers travel.

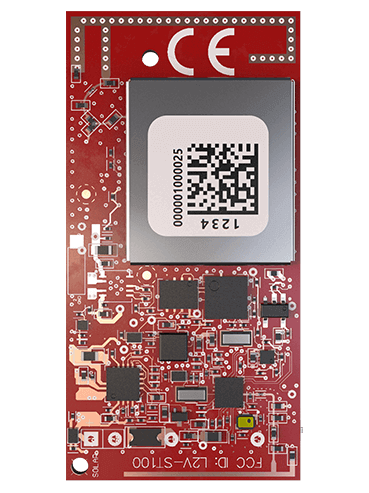

How do simple GPS coordinates save logistics companies millions of dollars? TGI has developed user-friendly serverless software and mobile phone applications that target the best opportunities for reducing costs. A major part of the winning technology is the Globalstar SmartOne asset tracker. Installed on trailers, this small and easy-to-mount solar-powered device is certified Intrinsically Safe (ATEX,HERO) for combustible environments. One of the most feature-rich satellite trackers on the market, it is powered by sunlight and delivers years of use with no maintenance. Integrated TGI sensors automatically detect when it is attached, monitors temperatures, creates driver assistance on demand and much more.

Managing Trailer Inventory

The savings begin with the costly assets that trucking companies operate. One TGI customer manages an inventory of hundreds of trailers, some company-owned and others rented by the month. In the first year of a contract with TGI, accurate information on its total trailer fleet enabled the company to eliminate 100 rented trailers with no impact on operations, saving $70,000 in monthly costs, or $840,000 annual costs. The company also had 40 new trailers on order because managers thought they were needed. Better data on location and utilization made it obvious that the company had sufficient inventory even after shedding 100 rental trailers. Canceling the order saving, another $1.2 million in immediate cost savings ($30,000 X 40 Trailers).

Finding Lost Assets

The manual yard check is a long tradition in the trucking business. Employees armed with clipboards walk the yards multiple times a day to identify all available trailers, a process that consumes hours every day. The handwritten inventory is then manually entered into data systems so that trailers can be matched with trucks and drivers. Since the trailers are constantly moving, even the timing of the yard checks can be outdated, leaving drivers to search for the trailers they have been told are somewhere in the yard.

One TGI customer estimates that it saves $100,000 per year by eliminating the yard check tradition at just six locations. The TGI system automatically tracks and maps the location and identity of every trailer. TGI software displays them and simplifies the task of assigning trailers to drivers, which can navigate the driver to the trailer using a mobile app. In addition to cutting waste, companies save their drivers time, fuel and wear-and-tear on vehicles, all of which sometimes come out of the driver’s pocket. “We save our drivers enough time,” said one TGI customer, “to haul an extra load per year. That’s money going back in their pocket.”

More Cost-Effective Maintenance

Trailer maintenance is an ongoing expense for trucking companies. Traditionally, companies schedule regular maintenance based on the calendar – but that has no relationship to actual wear and tear. TGI’s tracking solutions make it possible to develop accurate estimates of trailer milage based on Globalstar’s GPS data, integrated with TGI’s mileage software. For example, a One-thousand-unit carrier discovered that it was performing maintenance on trailers twice as often as needed. With maintenance per trailer consuming an average of $750 in cost per trailer, cutting maintenance activity in half generated meaningful savings of upwards of $750,000.

Better Billing for Detentions

A continuing source of tension between carriers and their customers is trailer detention. A driver drops off a trailer at a customer location for unloading – and getting it back from the customer becomes an ordeal. The customer may have more urgent priorities than unloading and returning a trailer. They may slip into using it for onsite storage. That dwell time, as it is called, is billable, but customers can deny that they are detaining the trailer or claim that it has been on their property for much less time. In a highly competitive business, you don’t usually win by arguing with the customer.

Tracking data brings arguments to a quick conclusion. TGI offers an application that tracks detentions and automatically generates invoices providing complete detail on dwell time as measured by Globalstar’s GPS. This application produced more than $80,000 per month in additional dwell time revenue for a Top 10 North American carrier that operates one of it’s 1,000 trailers divisions.

The Future of Logistics

Inspired by the power of satellite asset tracking, TGI is developing a new AI-driven sensor platform for the logistics market. Called Vizicube, it connects to onboard sensors tracking everything from doors opening, temperature monitoring, to trailer contents and more. Edge computing and machine learning use the data to generate intelligent messages for transmission through Globalstar’s SmartOne Solar tracker, which doubles as an IoT data transmitter. Such innovation has only made TGI more committed to satellite as a core technology. “The more you move into IoT solutions,” said TGI’s CEO, Bill Wright, “the more critical reliable connectivity becomes. In our business, satellite is always going to be the best option.”

SmartOne Solar

SmartOne Solar SmartOne C

SmartOne C ST100

ST100 STX3

STX3 SPOT X

SPOT X SPOT Gen4

SPOT Gen4 SPOT Trace

SPOT Trace