Combining IoT with satellites yields actionable intelligence to keep highly explosive gases safe

It's clear that when petrochemical companies ship potentially explosive products in rail tank cars and tank containers, it's critical that they know the location of their assets. However, today's advanced solutions that harness the Internet of Things, the latest hardware and software, as well as space-based technology, deliver myriad benefits far beyond simple track and trace.

Upon initially deploying the powerful Ovinto Sat asset tracking platform to its tanks a few years ago, leading petrochemical provider INEOS Oxide soon discovered a plethora of advantages additional to delivering the essential imperative of safety.

INEOS Oxide began its initial use of the Ovinto Sat system, created by Belgian innovator Ovinto, by carrying out track and trace on its tanks conveying Ethylene Oxide.

The Ovinto Sat tracking solution, based on Globalstar satellite technology, monitors the transport of INEOS Oxides petrochemical products in tanks. This solution reduces the risk in transportation by monitoring the condition of the chemicals in each vessel while providing valuable shipment information for the supply chain.

Such was the success of this initial deployment that INEOS expanded it and soon the Ovinto system was being used to track and monitor all rail tank cars and tank containers dedicated to the transport of its hazardous products, totalling over 700 device units to date. Ovinto Sat collates data from various sensors and GPS in transmitting devices installed on each of INEOS Oxide’s tank cars and containers, and sends it securely by satellite to customer operations teams at regular, user-defined intervals.

“Ovinto Sat’s innovative and powerful tracking platform helps our business in so many ways, the most important, of course being safe conveyance of our products,” says Business Safety, Health & Environmental (SHE) Manager at INEOS Oxide, Patrick De Block.

Ensuring safety

Two of the main products which INEOS Oxide transports are Ethylene Oxide and Propylene Oxide, primarily used to manufacture products for the following industries and applications: Agrochemicals, Construction, Pharmaceuticals & Personal Care, Solvents and Inks, Surfactants and detergents Both chemicals are highly explosive, flammable and carcinogenic to humans and animals.Ovinto Sat leverages IoT (Internet of Things) tracking to do much more than simply provide positioning data. “We always want to know where the real tank cars are, but the really important parameter we must know for safe transport is temperature.” After evaluating several alternatives in the marketplace, INEOS decided to deploy Ovinto’s complementary PT1000 solution that monitors the surface temperature of the tank’s or rail car’s contents. The temperature of the gases in transit is monitored every two hours. The solution has an online version and a local version, this duality deemed essential backup to validate the vessel's thermometer readings.

Critically, all Ovinto Sat solutions are certified to the very highest ATEX safety level for explosive materials.

Multiple operational benefits

While it’s vital that the transport of explosive chemicals is completely safe, De Block points out that the system also affords myriad operational benefits.This IoT-empowered solution gives INEOS Oxide instant updates about whether a rail tank car has been loaded or unloaded or is ready to be redeployed. This helps the company enhance return on investment and optimisation of assets.

In many cases, customers’ licences allow them to store the gases at a maximum of 25 degrees Celsius. Knowing the precise temperature of the products at all times enables the parties to optimise logistical arrangements. This not only ensures the safe transit and delivery of the products, it also ensures that delivery timetables meet the needs of both supplier and customer, commercially as well as for assurance of regulatory compliance.

Enabling informed and timely decision-making

The company uses the system to set up geofences around customer locations. The tracking data from Ovinto Sat enables INEOS Oxide to reliably provide granular detail on car or tank temperature alongside delivery logistics as the shipment nears its destination.“We are now able to harvest so much data, we can make informed predictions regarding temperature fluctuation, and any necessary requirement for refrigeration, as our shipments move across countries,” De Block notes.

Additionally, with the ability to monitor the location and status of each tank, all parties can be aware whether all commercial obligation have been met, or otherwise. “If we occasionally see that a customer is taking an unduly long time to unload a tank, we can investigate, and take appropriate action to get things back on track,” he adds.

Europe’s main transport corridors are risk-assessed, and that data is fed into Ovinto Sat. If for any reason a diversion occurs, INEOS Oxide‘s operational teams are alerted and have the ability to take any necessary mitigating action.

If road deliveries encounter delays due to traffic congestion for example, Ovinto Sat produces reliable data which enables local authorities to be apprised that the contents of the tanks in transit are safe.

Asset optimisation

Ovinto Sat’s event logging system is loaded with all technical details of the tank car, as well as maintenance requirements and schedules. Having a long term recorded history of each tank further enhances safety and informs technical decision making. “This system is active, continually emanating data, it's very useful for analysing trends and ensuring that each tank is technically performing as it should.” He shares that authorities appreciate that providers like INEOS Oxide have made investment in achieving this level of technical understanding.De Block stresses the importance that the tracking and monitoring system be reliable: “if the solution you're using is not completely reliable, you're lost.”

“Our deployment of Ovinto Sat has proven extremely useful to parties across the supply chain,” comments De Block. “There are other solutions on the market, but we know that ATEX-certified Ovinto Sat, with its reach and constancy enabled by Globalstar’s satellite technology, is the ideal solution for us,” he added.

He particularly appreciates Ovinto’s dedication to customer satisfaction and innovative problem-solving: “If ever a new challenge arises, we can rely on Ovinto to leap into gear and come up with a solution that's both innovative and, equally importantly, cost effective.”

An example of this commitment to innovation, additional to its hardware, Ovinto has also developed a reference Supply Chain Optimisation SaaS platform dedicated to rail and intermodal freight to support the IT infrastructure of its customers with complementary services that increase efficiency and reduce costs.

Keeping stakeholders informed

In the event of an emergency, Ovinto Sat can provide stakeholders and public authorities with a detailed understanding of the tank’s or rail car’s location and conditions.Critically, satellite technology enables all stakeholders to be confident that IoT transmissions from the tanks and cars are reliable, ubiquitous and uninterrupted. This delivers the very highest level of safety compliance, benefitting and protecting all supply chain partners as well as infrastructure authorities, and the organisations and people who rely on railways and roads.

Long battery life

INEOS Oxide has gained many learnings from trials of other solutions and technologies, including, for instance, the importance of battery management. Frequent changing of batteries incurs high operational costs and fundamentally changes the economics of a track and trace system.“The Ovinto Sat system is intrinsically energy efficient, and with the latest batteries lasting years, the resultant low maintenance cost sets it apart,” he comments.

Emerging enhancements to Ovinto Sat include the ability to accurately measure the amount of gas in a tank or rail car to help optimise these assets’ use. Explains De Block; “At this point, when a tank returns from the customer we assume that it has been unloaded; but really we would like a more precise verification of this.” De Block explains that an empty rail tank car heats up more rapidly than a full one. If a temperature rise is identified, there might be an assumption that the vessel is part filled and at risk, triggering alerts. But in reality, it might be empty and pose no danger.

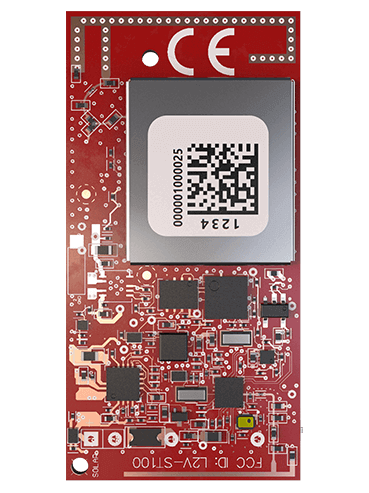

At the core of Ovinto Sat is Globalstar’s low power STX3 chipset, the smallest satellite transmitter of its kind in the market. Since it is battery powered, Ovinto Sat enables customers to monitor hazardous materials in unpowered environments such as rail cars and tanks. The Ovinto Sat battery can last up to eight years. The extra-long charge lifespan of the batteries used in Ovinto Sat yields its own benefits: “If we had to carry out maintenance on the devices or change the battery every year or half year, it would incur significant operational cost and make the solution uneconomic,” De Block explains.

Frederick Ronse, Ovinto CEO, commented: “With our ongoing engineering enhancements roadmap, new features will continue to help INEOS Oxide reduce risk, increase the safety of its cars and tanks, and enhance supply chain decision-making. Globalstar technology is our communications core due to its ubiquitous reach, reliability and low power consumption compared to GSM.”

“The matter of pure safety is of course paramount; we always need to know where our assets are, and we need to know the temperature of the contents, but the system is really helping us achieve optimisation of our processes,” De Block comments.

SmartOne Solar

SmartOne Solar SmartOne C

SmartOne C ST100

ST100 STX3

STX3 SPOT X

SPOT X SPOT Gen4

SPOT Gen4 SPOT Trace

SPOT Trace