How an Oilfield Services Company Monitors Tank Fluid Levels Without Leaving the Office

THE CHALLENGE

Oil is a precious fluid. Producing it, and the natural gas found with it, involves many other vital fluids as well, from friction reducers to stabilization chemicals. To maintain production, the fluid level in storage tanks at the drill site need regular monitoring. In the old days, a sight glass was the only option. Since then, dozens of measurement systems have been created, from floats and hydrostatic devices to capacitance transmitters. They get the job done – but are complex and costly to install and calibrate. They also need to be customized to the kind of fluid they measure.

There is more to monitoring than what happens in the tank. Checking gauges by hand is slow and costly, so tank monitoring is increasingly being handled remotely using a cellular connection between the tank and a monitoring location. Cellular has the advantage of being cheap, but it suffers from incompatibility. The SIM card that works in one place may not work in another mobile operator’s territory. For drilling rigs on the move, that adds more cost and complexity.

THE SOLUTION

After more than a decade solving these problems for oilfield services companies, Lasso Technologies came up with a better idea. The iRadar remote tank monitoring system is a turnkey device that bolts to an inspection port on top of poly, fiberglass or metal tanks up to 30 feet tall. It uses radar to measure the level of virtually any fluid, regardless of type (thick, foamy or caustic) or specific gravity. It transmits its readings of tank level plus GPS coordinates through the Globalstar satellite network to Lasso’s customer data portal, anywhere from once per day up to once per hour. Replaceable long-life batteries provide 3-5 years of operation before needing replacement.

Measuring Levels across West Texas

For one company, Lasso has equipped 36 tanks at drill sites across the Permian Basin in West Texas. Installation typically takes about 2 minutes without drilling or chemical contact. This compares with the typical installation process for tank monitoring, which involves modifying the tank, installing sensors and running cables at a cost of more than $2,000. Once Lasso trains company staff, they can do easily do the installations themselves. And iRadar runs without external power for years.

Configuration is equally quick and simple. The iRadar system comes with Bluetooth connectivity and a mobile phone app. Customers configure each installation on their phones, selecting the kind of material the tank is made from and its interior dimensions. Once that’s done, they can view current and historical fluid level right in the app.

“When we explain the iRadar to customers, they always have an ‘aha!’ moment,” says Lasso’s Daniel Irizarry. “They’ve been using another system and they’ve learned all the problems. So, the simplicity of iRadar really appeals to them. Once they start using it, it changes their business process. They spend less upfront, don’t have to replace sensors that wear out, and see their tank maintenance costs fall.”

Why Satellite?

The West Texas territory of this oilfield services company is served by two mobile carriers. Their coverage does not overlap. Before adopting iRadar, the company had to make sure which carrier covered a new location and get the appropriate SIM installed in its tank monitoring gear. Inevitably, the SIM was sometimes wrong, and the resulting confusion and delay cost the company. The Globalstar satellite network, on the other hand, covers the entire US and 80% of the world with a single, reliable platform.

Some customers question the wisdom of using satellite to transmit tank data. Isn’t satellite expensive? Don’t they need a bit antenna at the drill site?

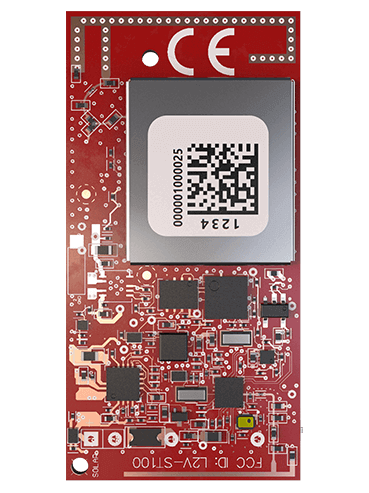

“The iRadar unit is small enough to hold in your hand,” says Martin Jefferson, Regional Sales Manager for Globalstar’s Commercial IoT Group. “Our ultra low power consumption STX-3 satellite transmitter, patch antenna, processor and battery power circuitry are all contained inside this compact housing. Installation could not be easier, combining technology with network affordability, setting the stage for partner innovation. The iRadar is another example of Globalstar partner ingenuity powered by a proprietary network of satellites that are Always On, and Always Reliable.”

Globalstar is proud to integrate its satellite technology into Industrial IoT systems from Lasso Technologies and many other innovative companies serving a wide range of industries. For more information, visit www.lasso.com or www.globalstar.com.

ABOUT LASSO TECHNOLOGIES

Founded in 2008, Lasso is an Industrial IoT company offering the industry’s most diverse integrated telematics system. What sets Lasso apart is the use of powerful web-based software and hardware technologies, such as sensors, GPS, RFID, and mesh technologies, communicating data over satellite, cellular or Wi-Fi networks, all of which enable us to provide our customers with a diverse suite of solutions that coalesce into a single interface. Its customers span a broad range of industries around the globe, including oil & gas, chemical, transportation & logistics, leasing, construction, government & environmental, food & beverage and agriculture. With them, we share an expansive vision and the courage to execute today’s most innovative and strategic telematics solutions.

SmartOne Solar

SmartOne Solar SmartOne C

SmartOne C ST100

ST100 STX3

STX3 SPOT X

SPOT X SPOT Gen4

SPOT Gen4 SPOT Trace

SPOT Trace