The Future of Manufacturing: Top 5 Benefits of Automation and Why Private Cellular Connectivity is Essential

Automation is revolutionizing the manufacturing sector – driving efficiency, productivity, and innovation. As manufacturers strive to stay ahead, adopting automation technologies – from robotics to AI-driven predictive maintenance – has become necessary. However, the backbone of this transformation isn’t just innovative machinery; it’s also the connectivity that enables seamless operations. While wired networks have traditionally been the go-to solution, private cellular connectivity is emerging as the superior choice for modern manufacturing. The top five benefits of automation in manufacturing (and how private cellular networks intersect) are:

1. Enhanced Productivity and Efficiency

Automation eliminates bottlenecks in product processes, reduces human error, and ensures machines operate at peak efficiency. Automated production lines can work 24/7 with minimal downtime, increasing output and meeting rising market demands. Moreover, intelligent automation systems use real-time data to optimize workflows, preventing slowdowns and inefficiencies.Why private cellular? Unlike wired networks, which can be restrictive and difficult to scale, private cellular networks offer seamless connectivity across vast factory floors. This in turn enables the automated systems communicate in real time without the limitations of physical cabling, allowing for more flexible and dynamic operations.

2. Improve Safety and Workplace Conditions

With automation handling hazardous and repetitive tasks, manufacturers can significantly reduce workplace injuries. Robots and AI-driven machines can take on high-risk operations, such as heavy lifting, extreme temperatures, or exposure to toxic substances, ensuring that human workers stay out of harm’s way.Why private cellular? Safety-enhancing technologies like autonomous guided vehicles (AGVs) and remote monitoring systems rely on uninterrupted, low-latency communication. Private cellular networks provide stable, high-speed connections, ensuring real-time safety monitoring, immediate hazard detection, and reliable emergency response capabilities.

3. Higher Quality and Consistency

One key advantage of automation is the ability to maintain high-quality product standards. Automated systems can execute tasks with extreme precision, reducing defects and inconsistencies arising from human errors. AI-powered analytics refines quality control processes by detecting and addressing issues before they escalate.Why private cellular? A robust cellular network ensures that automated quality control systems, such as IoT-enabled sensors and AI-driven cameras, can operate without interruptions. Unlike wired networks, which may experience disruptions due to physical wear and tear, private cellular offers uninterrupted connectivity for consistent real-time monitoring and analysis.

4. Scalability and Flexibility

As businesses grow and evolve, the ability to scale operations without major infrastructure overhauls is crucial. Automation allows manufacturers to adapt quickly to market changes, introduce new product lines, and optimize production schedules based on demand.

Why private cellular? Private cellular networks offer greater flexibility compared to wired solutions, which require extensive rewiring when scaling up operations. Wired networks enable easy integration of new automated machines and IoT devices without the need for complex and costly infrastructure changes, making expansion seamless and cost-effective.

5. Data-Driven Decision-Making

Automation generates vast amounts of data that can be analyzed to improve efficiency, reduce costs, and enhance decision-making. AI-driven analytics help manufacturers predict maintenance needs, optimize resource allocation, and improve operational performance.Why private cellular? The speed and reliability of data transmission are critical for effective automation. Private cellular networks provide high-speed, low-latency connectivity, ensuring that real-time data from automated systems is transmitted without delays. This allows manufacturers to make informed decisions instantly, enhancing productivity and reducing downtime.

Optimizing Private Cellular Networks for Automation

Automation is undoubtedly a driving force behind the next industrial revolution, offering unmatched benefits in efficiency, safety, quality, scalability, and data utilization. However, to fully unlock the potential of automation, manufacturers must move away from traditional wired networks and embrace private cellular connectivity. With its flexibility, reliability, and scalability, private cellular ensures that automated systems operate seamlessly, enabling manufacturers to stay competitive in an increasingly digitalized world.

As manufacturing continues to evolve, those who integrate automation with the proper connectivity solutions will lead the way in innovation, efficiency, and profitability. The future of manufacturing isn’t just automated – it’s private cellular.

Learn more about how Globalstar’s XCOM RAN seamlessly helps organizations realize the actual benefits of private cellular networking.

SmartOne Solar

SmartOne Solar SmartOne C

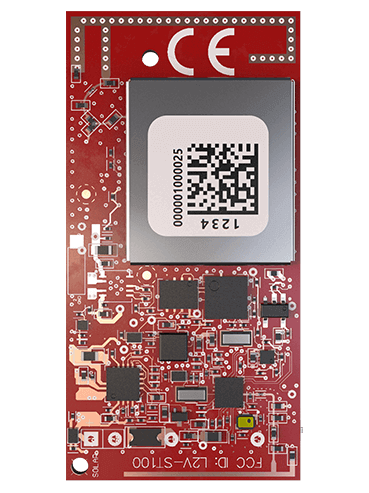

SmartOne C ST100

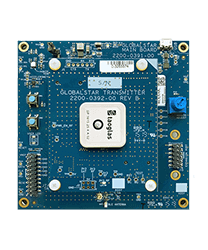

ST100 STX3

STX3 STX3 Dev Kit

STX3 Dev Kit SPOT X

SPOT X SPOT Gen4

SPOT Gen4 SPOT Trace

SPOT Trace