Listening for the Level of Fluid in Mission-Critical Tanks

THE CHALLENGE

In your home, you turn on a tap and water flows. If you cook with natural gas, you turn a knob on your stove and the burner lights. But for some of the most critical applications in business and government, access to a valuable resource depends on how much is left in a tank of fixed volume, which must be refilled by via a supply chain. Adding to the challenge is the fact that many of these tanks are in remote areas, where there is no power or wireless coverage for monitoring. And that creates problems.

When Infrastructure Fails

When natural disaster strikes, telecommunications are often the first thing to fail due to damage or loss of power. To cover the gap, governments maintain emergency communications networks, but these depend on backup generators fueled from storage tanks. Ensuring that every tank has adequate fuel when it is needed means manual inspection of gauges – a costly and inefficient process that is all too prone to error.

Unpredictable Demand

Propane has an enormous range of uses, from manufacturing materials to powering industrial machinery and transportation. Heating homes and cooking food makes up almost half of global consumption. Those users depend on a supply chain of distributors to keep the gas flowing. But for distributors, keeping customer tanks supplied and their own tanks filled is too often a matter of guesswork based on past consumption trends, [or manual checks] which leads to too many or too few costly deliveries to efficiently meet current needs.

Irrigation Management

On the farm, water is life. Crops need irrigation to survive in dry weather. Beef cattle that go without water for 24 hours experience a measurable reduction in growth. Farmers and ranchers can’t drill wells everywhere water is needed, so they rely on tanks for storage and must sometimes travel for hours just to make sure there is an adequate supply.

THE SOLUTION

Schmitt Measurement System (SMS) is an Oregon-based provider of high-precision measurement products. Its Xact line of tank monitoring systems brings affordable, reliable, and secure satellite technology to the problem of monitoring vital tank levels regardless of available wireless connectivity. Xact products utilize a variety of sensors to determine the fill levels of fluid-filled tanks without any modification to the tank itself. For example, SMS’s patented industry leading, ultrasonic sensor measures accurately from the outside of a tank. The sensor is able to detect the surface level of tank contents. A control unit determines the height of the liquid’s surface above the tank floor and calculates the volume of liquid using previously entered tank dimensions and the current temperature.

The control unit also contains a Globalstar satellite STX3 modem module, which periodically transmits the calculated volume through its onboard antenna over the Globalstar Satellite Network, delivering the data to the SMS’ customer portal, where maps, charts and tables provide current and historical data to computers and phone apps. The modem offers low power consumption in a compact build not much bigger than a quarter and is easily integrated into specialized technology.

Keeping Fuel Tanks Filled

The Xact system gives the managers of emergency communications networks a global view of fuel levels in every tank in their system. The data, displayed on computers or phones, can identify leaking tanks, optimize the scheduling of maintenance and refill visits, and prevent tanks from running dry when they are most needed.

Optimizing the Supply Chain

With Xact, propane distributors can remotely monitor the level in every tank they service every day. This data can bring a new level of efficiency to operations, from better managing their own propane supply to usage-based delivery by fewer trucks and personnel. It also ensures customer satisfaction with a fuel supply that is always available.

Keeping the Water Flowing

Data from Xact systems on their water tanks can save farmers and ranchers thousands of person-hours a year on manual inspection of tank levels, while drawing attention to real problems. Changing tank levels can signal a leak that needs repair, while static levels may indicate a failed pump. The flow of data from field to their computer or phone screens ensures that the flow of water will keep crops and animals healthy on their journey from farm to table.

ABOUT SCHMITT MEASUREMENT SYSTEMS

SCHMITT MEASUREMENT SYSTEMS designs, manufactures, and sells high-precision test and measurement products, solutions, and services through its Acuity® and Xact® product lines. Acuity provides laser and white light sensor distance measurement and dimensional sizing products, and the Xact line provides remote tank monitoring products.

SmartOne Solar

SmartOne Solar SmartOne C

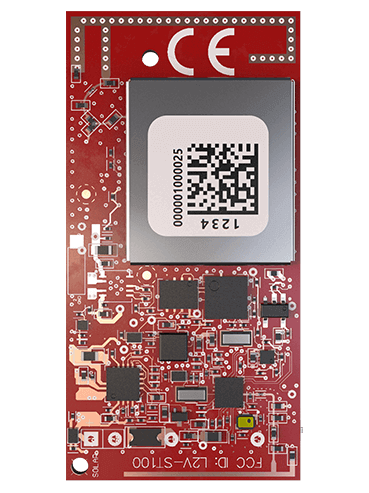

SmartOne C ST100

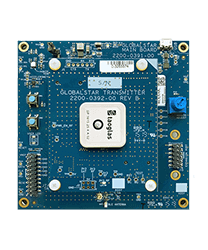

ST100 STX3

STX3 STX3 Dev Kit

STX3 Dev Kit SPOT X

SPOT X SPOT Gen4

SPOT Gen4 SPOT Trace

SPOT Trace